- Chemical processing

- Pharmaceutical production

- Food processing

- Laboratory research

These reactors offer numerous advantages due to their glass lining:

- Superior Corrosion Resistance: Withstands harsh chemicals like acids, alkalis, and salts.

- Easy Cleaning and Disinfection: Smooth glass surface simplifies cleaning and sterilization.

- Material Inertness: Glass doesn't react with materials, preventing contamination.

- Excellent Transparency: Allows for visual monitoring of the reaction process.

- Wide Temperature Range: Operates effectively between -80℃ and 200℃.

Our Flange Glass-Lined Reactors:

We are committed to providing high-quality flange glass-lined reactors, characterized by:

- Exceptional Performance and Reliability: We utilize top-grade glass materials and meticulous manufacturing processes.

- Durability and Dependability: Stringent testing and quality control ensure operation under demanding conditions.

- Customization Options: We tailor the reactor to your specific needs, including size, specifications, and configuration.

- Broad Application Suitability: Our reactors are ideal for various chemical reactions like synthesis, decomposition, distillation, and crystallization.

- Comprehensive After-Sales Support: We offer installation, commissioning, and maintenance services.

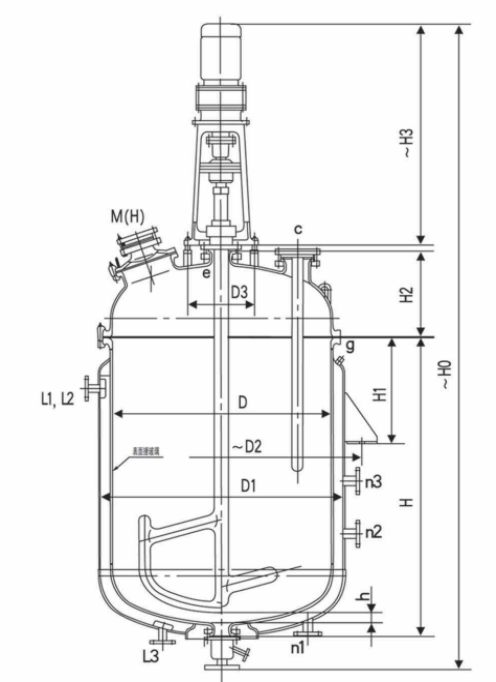

Flange Type Glass-Lined Reactor: Advantages and Considerations

Advantages:

- Cost-Effective Maintenance: Flanged design (open-type) allows for individual cover or body replacement when damaged.

- Enhanced Homogenization: The flanged design accommodates anchor agitators, ideal for high-viscosity materials.

Considerations:

- Volume Limitations: Furance-based glass lining may cause slight deformations, limiting the recommended volume to 16,000L.

- Pressure Applications: Larger sealing surfaces between the cover and body may increase the risk of leakage at high pressures. Careful selection is advised.

Our Equipment's Edge:

- Premium Czech Enamel: We utilize high-quality imported Czech enamel and strictly adhere to the cold enamel process for consistent material and process quality.

- Rigorous Quality Control: Every reactor undergoes thorough size measurements, water pressure tests, air pressure tests, and high-voltage spark tests before leaving the factory.

- Superior Components: We employ top-of-the-line components, including stainless steel PTFE gaskets, galvanized anti-corrosion clamps, and nuts and bolts.

We are confident that our flange glass-lined reactors can meet your specific requirements. Contact us today to discuss your needs and explore how we can help!