I.Features of monoblock type glass lined reactor:

Advantage:

1. Monoblock glass-lined reactor is also called closed-type glass-lined reactor. The cover and body of the reactor are welded together. Therefore, the strength of the reactor itself is better, and it is less likely to be deformed.

2. The closed glass-lined reactor can have a smaller sealing surface and better sealing performance.

Disadvantages:

1. Because the reactor cover is small, it is impossible to install an anchor agitator. Therefore, the use of closed reactor is relatively not recommended for high viscosity materials.

2. Since the tank cover and the shell are directly welded together, when the reactor is damaged, it needs to be repaired as a whole, and the maintenance cost is higher.

Our equipment advantages:

1. Our glass-lined reactor adopts high-quality imported Czech enamel and strictly abides by the cold enamel process to ensure the strict compliance of materials and procedures in the manufacturing process.

2. After the equipment is produced, it undergoes strict size measurement, water pressure and air pressure test, and high voltage electric spark test to ensure that all equipment has no quality problems before leaving the factory.

3. The equipment uses high-quality accessories, stainless steel PTFE gaskets, galvanized anti-corrosion clips, nuts and bolts, and every detail is well done.

Equipment Design Data

| Shell |

|

| Single Seal | Double Seal | Jacket |

| Design Pressure(MPa): | -0.1-0.4 | -0.1-0.6 | 0.6 |

| Working pressure(Mpa): | -0.1-0.4 | -0.1-0.6 | 0.6 |

| Design Temperature(℃): | -19-200 | -19-200 | 200 |

| Working Temperature(℃): | -19-180 | -19-180 | 200 |

| High Voltage Test(KV): | 20 |

|

| Enamel Thickness(mm): | 0.8-2.0 |

|

| Application Medium: | It can withstand the corrosion of various concentrations of organic acids, inorganic acids, organic solvents and weak alkalis (except for hydrofluoric acid, fluoride ion-containing media, the phosphoric acid and strong alkali concentration is greater than 30%, and the temperature is greater than 180 degrees Celsius). |

|

|

|

|

|

|

|

|

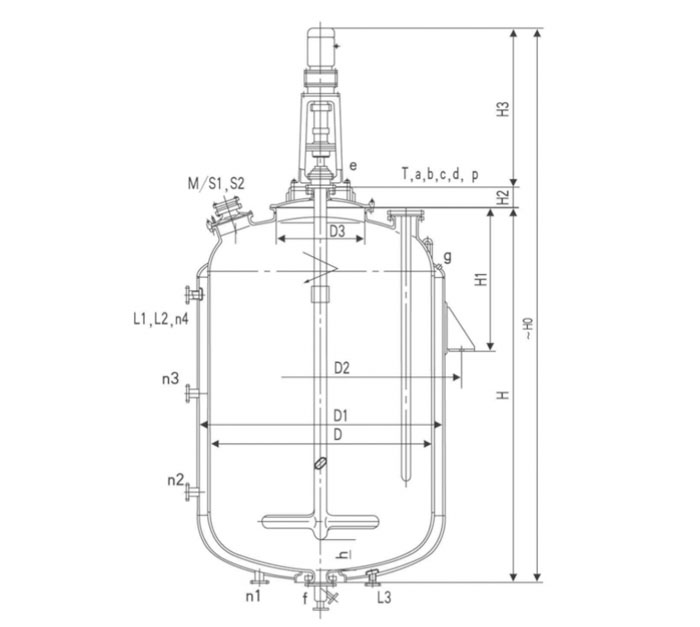

Equipment Dimension Sheet

| Nominal Capacity(L) | Actual Capacity(L) | Heat Exchange Area(m2) | Motor Power(Kw) | Main Dimension(mm) | Weight(Kg) |

| D | D1 | D2 | D3 | D4 | H | H1 | H2 | H3 | H0 |

| F1000 | 1520 | 4.93 | 3 | 1200 | 1300 | 1488 | --- | --- | 1610 | 850 | --- | 1154 | 3200 | 1151 |

| F1500 | 1961 | 5.35 | 4 | 1300 | 1450 | 1622 | 500 | --- | 1770 | 870 | --- | 1276 | 3486 | 1465 |

| F2000 | 2180 | 7.16 | 4 | 1300 | 1450 | 1622 | 500 | --- | 2190 | 990 | --- | 1276 | 3907 | 1778 |

| F2500 | 3385 | 8.68 | 4 | 1600 | 1750 | 1981 | 600 | --- | 2105 | 1140 | 195 | 1276 | 3937 | 2203 |

| F3000 | 3811 | 8.61 | 5.5 | 1600 | 1750 | 1964 | 600 | --- | 2325 | 1140 | 195 | 1316 | 4300 | 2629 |

| F5000 | 5905 | 13.16 | 7.5 | 1750 | 1900 | 2170 | 600 | --- | 2960 | 1200 | 195 | 1316 | 5000 | 3901 |

| F6300 | 6866 | 16 | 7.5 | 1750 | 1900 | 2196 | 600 | --- | 3345 | 1200 | 195 | 1475 | 5200 | 4349 |

| F8000 | 9060 | 18.38 | 7.5 | 2000 | 2200 | 2502 | 800 | --- | 3385 | 1440 | 200 | 1545 | 5360 | 6044 |

| F10000 | 11674 | 21.35 | 11 | 2200 | 2400 | 2734 | 800 | --- | 3628 | 1380 | 200 | 1770 | 5810 | 7427 |

| F12500 | 13651 | 24.89 | 15 | 2200 | 2400 | 2734 | 800 | --- | 4128 | 1500 | 200 | 1770 | 6330 | 8556 |

| F16000 | 17463 | 29.48 | 18.5 | 2400 | 2600 | --- | 800 | 1800 | 4421 | 1500 | 200 | 1865 | 6718 | 11178 |

| F20000 | 21790 | 34.03 | 18.5 | 2600 | 2800 | --- | 900 | 2000 | 4750 | 1500 | 210 | 1865 | 7026 | 13357 |

| F30000 | 32520 | 43.85 | 22 | 3000 | 3200 | --- | 900 | 2400 | 5356 | --- | 210 | 2025 | 7816 | 17985 |

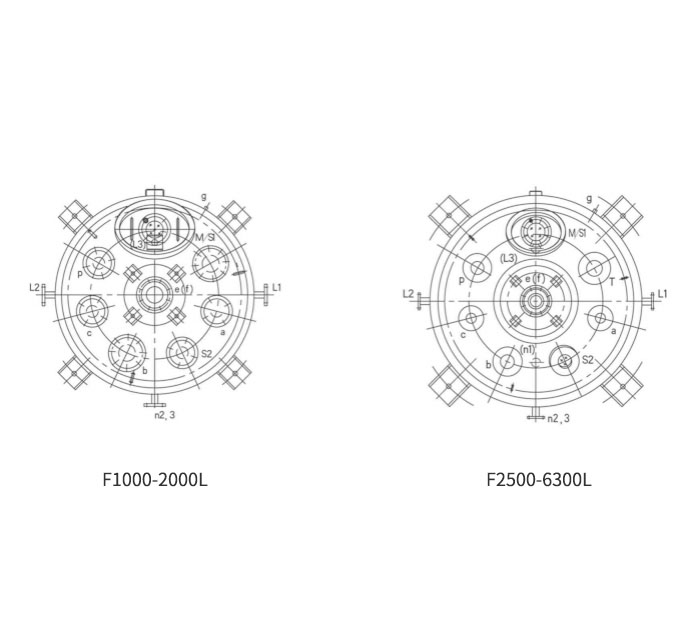

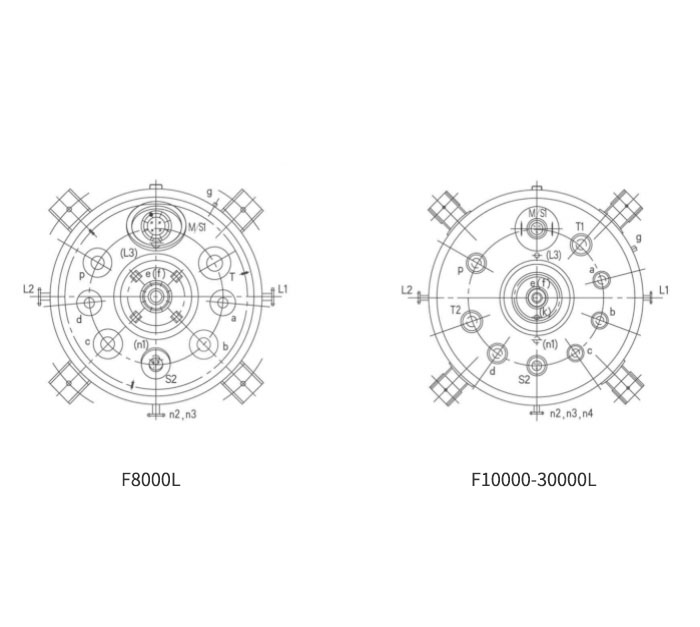

Nozzle Specifications

| Nominal Capacity(L) | Manhole | Agitator | Sightglass&Lantern | Thermowell pocket | Spare | Spare | Spare | Spare | Discharge | Inlet | Inlet | Outlet | Steam Inlet | Pressure guage | Vent |

| M | e | S1,S2 | T1 | T2 | a | b | c | d | f | n1-2 | n3 | n4 | L1-3 | P | g |

| F1000 | 300X400 | 125 | 100 | 100 | --- | 100 | 125 | 100 | --- | 100 | --- | --- | --- | 32 | --- | G3/4" |

| F1500 | 300X400 | 125 | 125 | 100 | --- | 100 | 125 | 100 | --- | 100 | 50 | --- | --- | 40 | --- | G3/4" |

| F2000 | 300X400 | 125 | 125 | 100 | --- | 100 | 125 | 100 | --- | 100 | 50 | --- | --- | 40 | --- | G3/4" |

| F2500 | 300X400 | 125 | 125 | 100 | --- | 100 | 125 | 100 | --- | 125 | 65 | --- | --- | 50 | --- | G3/4" |

| F3000 | 300X400 | 150 | 125 | 100 | --- | 100 | 125 | 100 | --- | 125 | 65 | --- | --- | 65 | --- | G3/4" |

| F5000 | 300X400 | 150 | 125 | 125 | --- | 125 | 150 | 150 | --- | 125 | 65 | 65 | --- | 65 | --- | G3/4" |

| F6300 | 300X400 | 150 | 125 | 125 | --- | 125 | 150 | 150 | --- | 125 | 65 | 65 | --- | 65 | --- | G3/4" |

| F8000 | 300X400 | 200 | 125 | 150 | --- | 150 | 150 | 150 | 150 | 125 | 80 | 80 | --- | 80 | --- | G3/4" |

| F10000 | 300X400 | 200 | 125 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 80 | 80 | 80 | 80 | --- | G3/4" |

| F12500 | 300X400 | 200 | 125 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 80 | 80 | 80 | 80 | --- | G3/4" |

| F16000 | 450 | 200 | 125 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 100 | 100 | 100 | 100 | --- | G3/4" |

| F20000 | 450 | 200 | 125 | 200 | 250 | 250 | 200 | 200 | 200 | 150 | 100 | 100 | 100 | 100 | --- | G3/4" |

| F30000 | 450 | 200 | 125 | 200 | 200 | 150 | 150 | 150 | 150 | 150 | 100 | 100 | 100 | 100 | 125 | G3/4" |