1. Scope of application

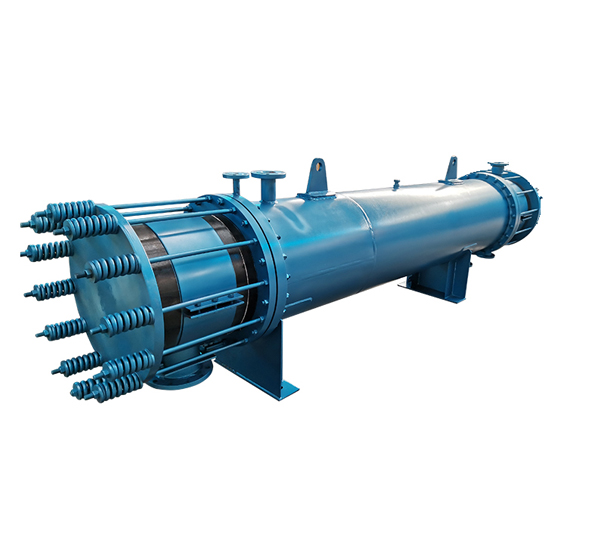

Graphite heat exchangers have excellent corrosion resistance and heat transfer performance, are suitable for heat transfer processes with corrosive media, are resistant to acids, alkalis and other corrosive media, and are widely used in the fields of organic chemistry and inorganic chemistry.

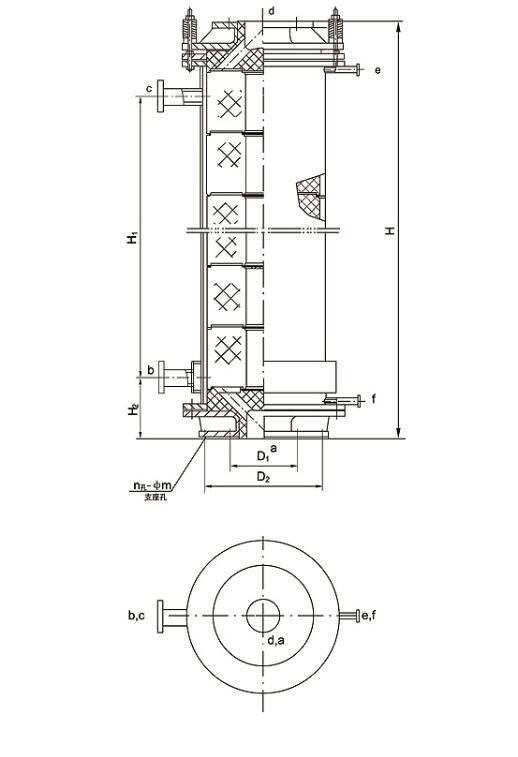

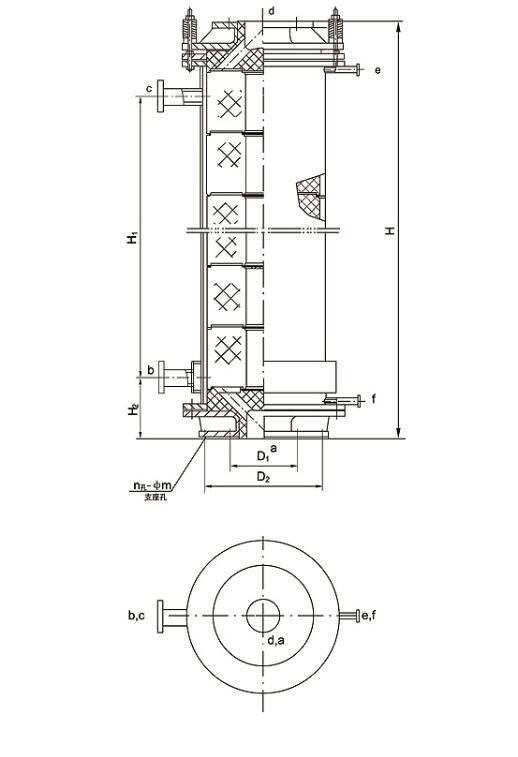

Graphite heat exchangers are mainly used for the operation of chemical units such as heating, cooling, condensation, evaporation and absorption. According to the characteristics of different materials, we provide different design schemes. According to their structure, they can be divided into round hole type and rectangular type. , Tube type, spray type, immersion type, etc.

2. Performance characteristics

· According to different process materials, both tube side and shell side can be corrosive materials

· Choosing different impregnants to impregnate graphite to withstand different process materials

· Has good heat transfer coefficient and expansion coefficient

· Heat exchange area up to 1500m2

· Through surface treatment, it can have a certain degree of wear resistance

· Lower pressure drop

· Both process side and service side can be emptied

· Easy to clean, maintain and disassemble

· Standardized design, the heat exchange area can be enlarged by increasing the number of holes or tubes

· We have a reasonable inventory. When you need spare parts, we will send the materials to you in a short time.

3. Technical characteristics

Design pressure: -0.098~1.0MPa

Working tempreture:220°C

Medium: Water/steam/heat transfer oil/corrosive materials

Heat exchange area: 1~1000m2

Aperture: Φ10 Φ12 Φ16 Φ18 Φ20 or greater