Our SS glass lined reactors are made from high-grade stainless steel and glass, offering exceptional corrosion resistance, abrasion resistance, and easy cleaning to meet the demands of a wide range of harsh chemical reactions.

Product Features:

- Superior Corrosion Resistance: Withstands various acids, alkalis, salts, and other corrosive chemicals.

- Excellent Abrasion Resistance: The glass lining possesses extreme hardness and smoothness, enduring high-intensity wear and tear.

- Easy Cleaning: The smooth glass surface facilitates effortless cleaning and sterilization.

- Wide Temperature Range: Can be used within a temperature range of -80℃ to 200℃.

Customization Available: We can customize SS glass lined reactors to your specific requirements, including size, specifications, and configuration.

SS Glass Lined Reactors are Ideal for:

Equipment Design Data

| Shell |

|

| Single Seal | Double Seal | Jacket |

| Design Pressure(MPa): | -0.1-0.4 | -0.1-0.6 | 0.6 |

| Working pressure(Mpa): | -0.1-0.4 | -0.1-0.6 | 0.6 |

| Design Temperature(℃): | -19-200 | -19-200 | 200 |

| Working Temperature(℃): | -19-180 | -19-180 | 200 |

| High Voltage Test(KV): | 20 |

|

| Enamel Thickness(mm): | 0.8-2.0 |

|

| Application Medium: | It can withstand the corrosion of various concentrations of organic acids, inorganic acids, organic solvents and weak alkalis (except for hydrofluoric acid, fluoride ion-containing media, the phosphoric acid and strong alkali concentration is greater than 30%, and the temperature is greater than 180 degrees Celsius). |

|

|

|

|

|

|

|

|

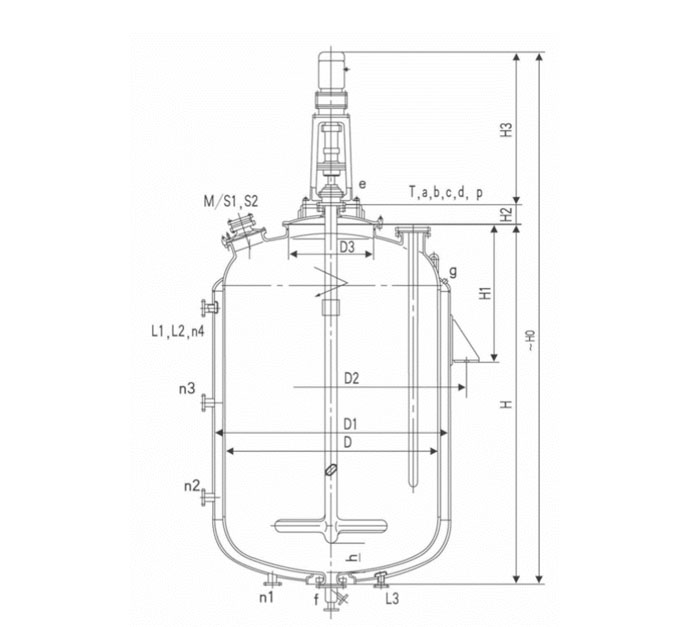

Equipment Dimension Sheet

| Nominal Capacity(L) | Actual Capacity(L) | Heat Exchange Area(m2) | Motor Power(Kw) | Main Dimension(mm) | Weight(Kg) |

| D | D1 | D2 | D3 | D4 | H | H1 | H2 | H3 | H0 |

| F1000 | 1520 | 4.93 | 3 | 1200 | 1300 | 1488 | --- | --- | 1610 | 850 | --- | 1154 | 3200 | 1151 |

| F1500 | 1961 | 5.35 | 4 | 1300 | 1450 | 1622 | 500 | --- | 1770 | 870 | --- | 1276 | 3486 | 1465 |

| F2000 | 2180 | 7.16 | 4 | 1300 | 1450 | 1622 | 500 | --- | 2190 | 990 | --- | 1276 | 3907 | 1778 |

| F2500 | 3385 | 8.68 | 4 | 1600 | 1750 | 1981 | 600 | --- | 2105 | 1140 | 195 | 1276 | 3937 | 2203 |

| F3000 | 3811 | 8.61 | 5.5 | 1600 | 1750 | 1964 | 600 | --- | 2325 | 1140 | 195 | 1316 | 4300 | 2629 |

| F5000 | 5905 | 13.16 | 7.5 | 1750 | 1900 | 2170 | 600 | --- | 2960 | 1200 | 195 | 1316 | 5000 | 3901 |

| F6300 | 6866 | 16 | 7.5 | 1750 | 1900 | 2196 | 600 | --- | 3345 | 1200 | 195 | 1475 | 5200 | 4349 |

| F8000 | 9060 | 18.38 | 7.5 | 2000 | 2200 | 2502 | 800 | --- | 3385 | 1440 | 200 | 1545 | 5360 | 6044 |

| F10000 | 11674 | 21.35 | 11 | 2200 | 2400 | 2734 | 800 | --- | 3628 | 1380 | 200 | 1770 | 5810 | 7427 |

| F12500 | 13651 | 24.89 | 15 | 2200 | 2400 | 2734 | 800 | --- | 4128 | 1500 | 200 | 1770 | 6330 | 8556 |

| F16000 | 17463 | 29.48 | 18.5 | 2400 | 2600 | --- | 800 | 1800 | 4421 | 1500 | 200 | 1865 | 6718 | 11178 |

| F20000 | 21790 | 34.03 | 18.5 | 2600 | 2800 | --- | 900 | 2000 | 4750 | 1500 | 210 | 1865 | 7026 | 13357 |

| F30000 | 32520 | 43.85 | 22 | 3000 | 3200 | --- | 900 | 2400 | 5356 | --- | 210 | 2025 | 7816 | 17985 |