Glass lined thermowell pocket instruction:

The glass-lined thermowell pocket usually does not exist alone, but works together with the stirrer. The thermowell pocket enters the tank through the thermowell port. The nozzle of the pocket is provided with a supporting fixed flange to connect to the reactor. The hair of the nozzle. Simple structure, convenient installation and operation, can be firmly fixed, safe and reliable, can ensure stable production, good application performance, and facilitate popularization and application. Glass-lined thermowell flanges include right-angle, inclined flange, blade type, anchor type, frame type, paddle type, impeller type stirring, stirring and thermowell casing are divided into 2 standard.

The nominal pressure of the glass-lined thermowell casing in the glass-lined reaction tank is 0.6MPa and 1.0MPa, and the medium temperature is generally 120℃~200℃.

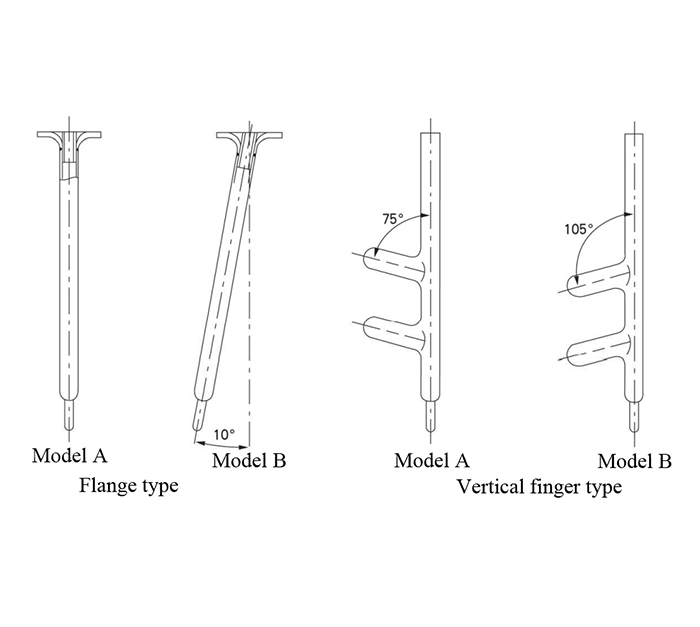

It can also be divided into two types in terms of structure, A type and B type, of which A type is without temperature measuring head device, and its nominal diameter is 32~80mm. Type B is a glass-lined thermowell pocket with a temperature probe device, with a nominal diameter of 50~80mm. The installation methods of glass-lined thermowell pockets are A-type and B-type, A-type is used for matching frame-type glass-lined stirrer, the installation angle is 0°, and B-type is used for matching anchor-type glass-lined stirrer, and the installation angle is 7° .

Glass-lined finned thermowell pocket is a thermowell pocket for glass-lined reactor stirring vessel equipped with paddle and impeller stirrers. The nominal pressure is 0.6MPa and 1.0MPa, and the medium temperature is -20~200℃.

Different types of reactor stirring devices need to be equipped with different types of thermowell pocket devices to accurately and timely measure the reaction temperature of the internal flow of the reactor, so as to adjust the temperature in time to ensure the smooth progress of the flow reaction.

Manufacturing in strict accordance with national standards. Various high-quality enamels such as special acid, alkali and imported enamel. Using cold grouting process. It has high hardness, high temperature resistance, wear resistance and insulation. At the same time, it has strong corrosion resistance to various concentrations of inorganic acids, organic acids, organic solvents and weak alkalis.